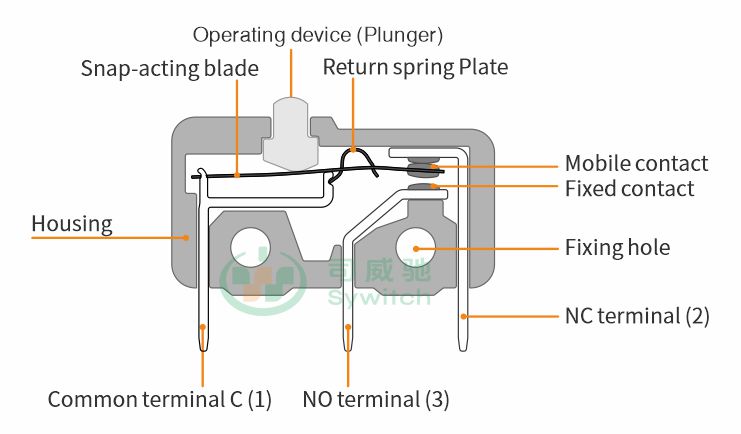

As shown in the figure above, this is a basic structure diagram of a double-acting micro switch, which includes a series of components and structures such as Housing, Actuators, Contact Points, Terminals, Snap-acting Blade, Return Spring Plate, Fixing Hole, etc.

The Housing, which is the enclosure of the micro switch, is typically made of materials such as PC plastic, nylon, and other primary raw materials. Depending on the specific characteristics and usage requirements of the switch, special materials such as flame retardants and glass fibers are added during the injection molding process. The Housing not only protects and fixes the internal components of the micro switch but also provides necessary Fixing Holes for the installation and use of the micro switch.

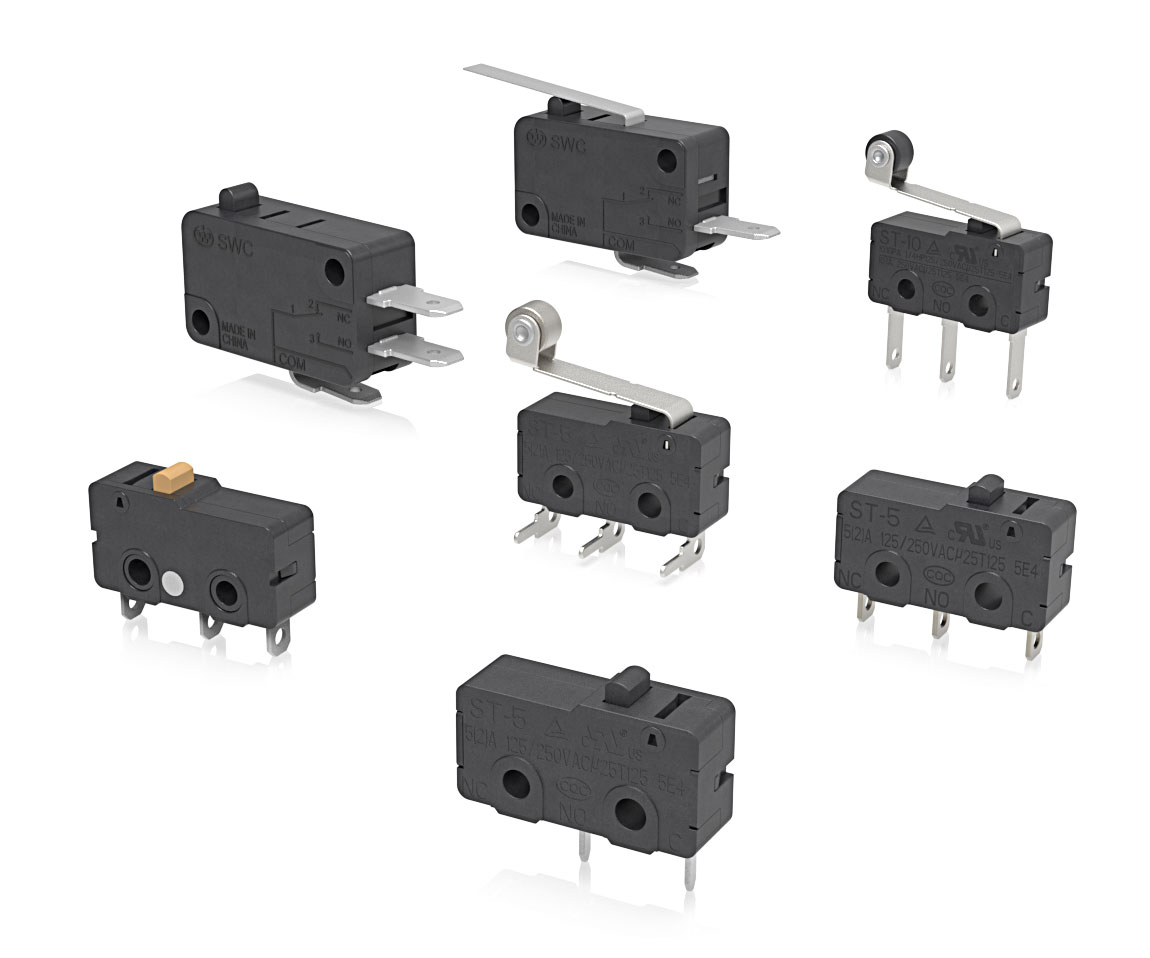

The Actuators are the driving mechanical structures of the micro switch. By default, they are in the form of a Plunger structure, but additional auxiliary driving parts such as Levers, Rollers, Dummy Rollers, etc., can be selected and installed to meet the requirements of different driving methods such as buttons, sliders, baffles, cams, or to achieve a smaller driving force and a wider range of buffering amplitude.

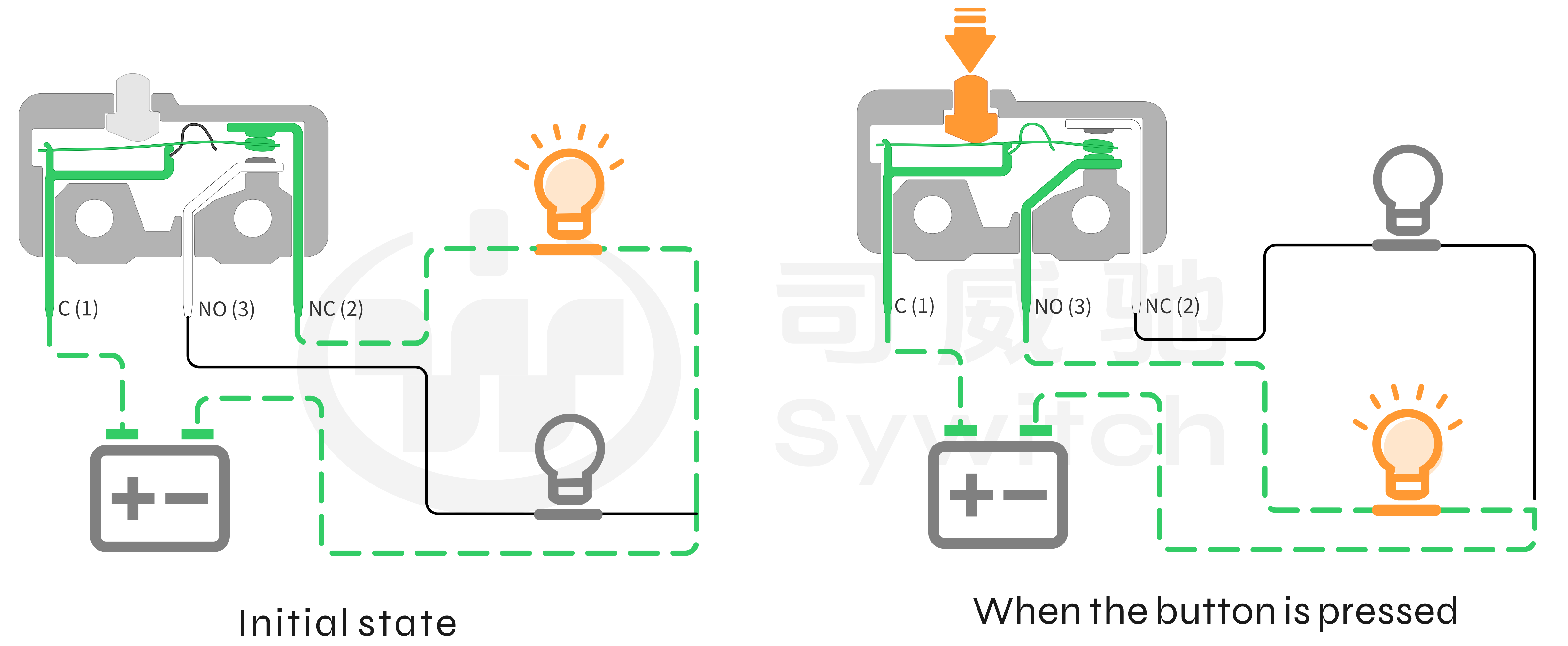

The Contact Point is an essential electrical structure in a micro switch, consisting of a Fixed Contact and a Mobile Contact. Typically, the Mobile Contact is movable and connected to the Common Terminal (C) via the Snap-acting Blade, while the Fixed Contact serves as the contact point for the NO (Normally Open) Terminal and the NC (Normally Closed) Terminal.

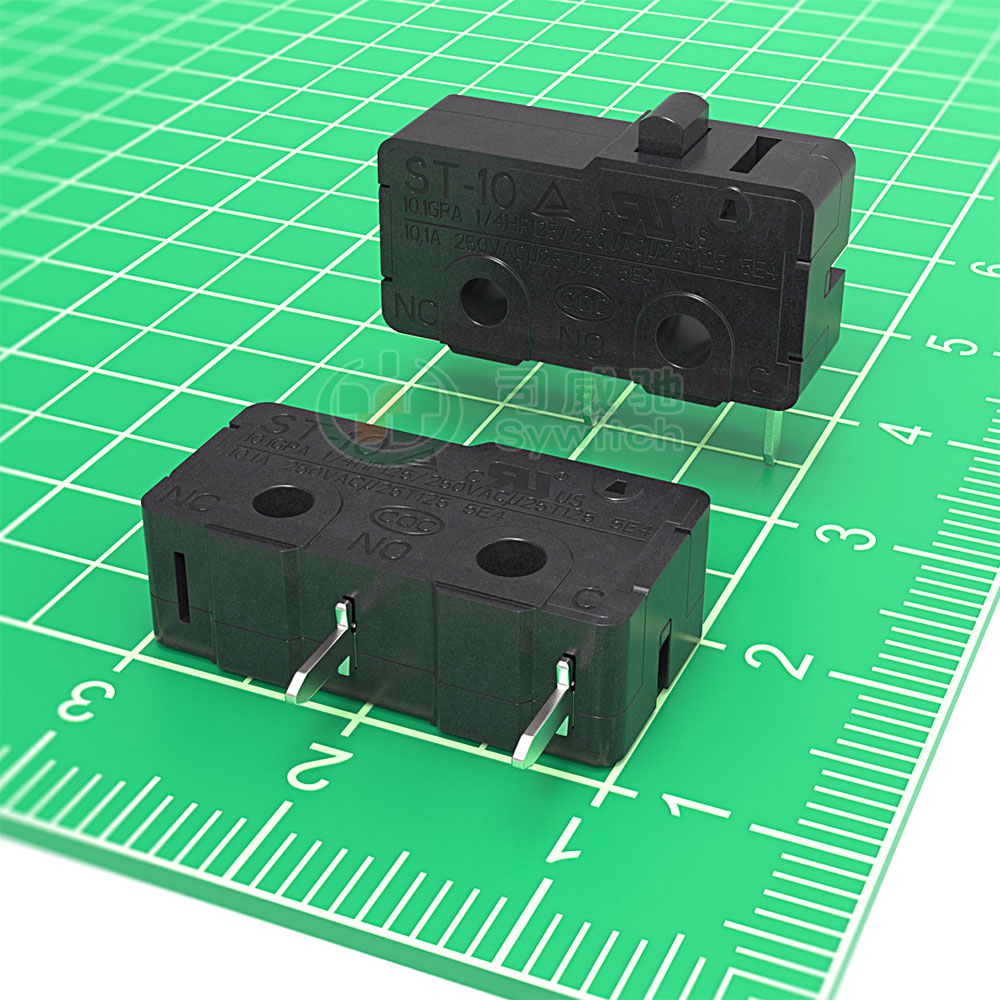

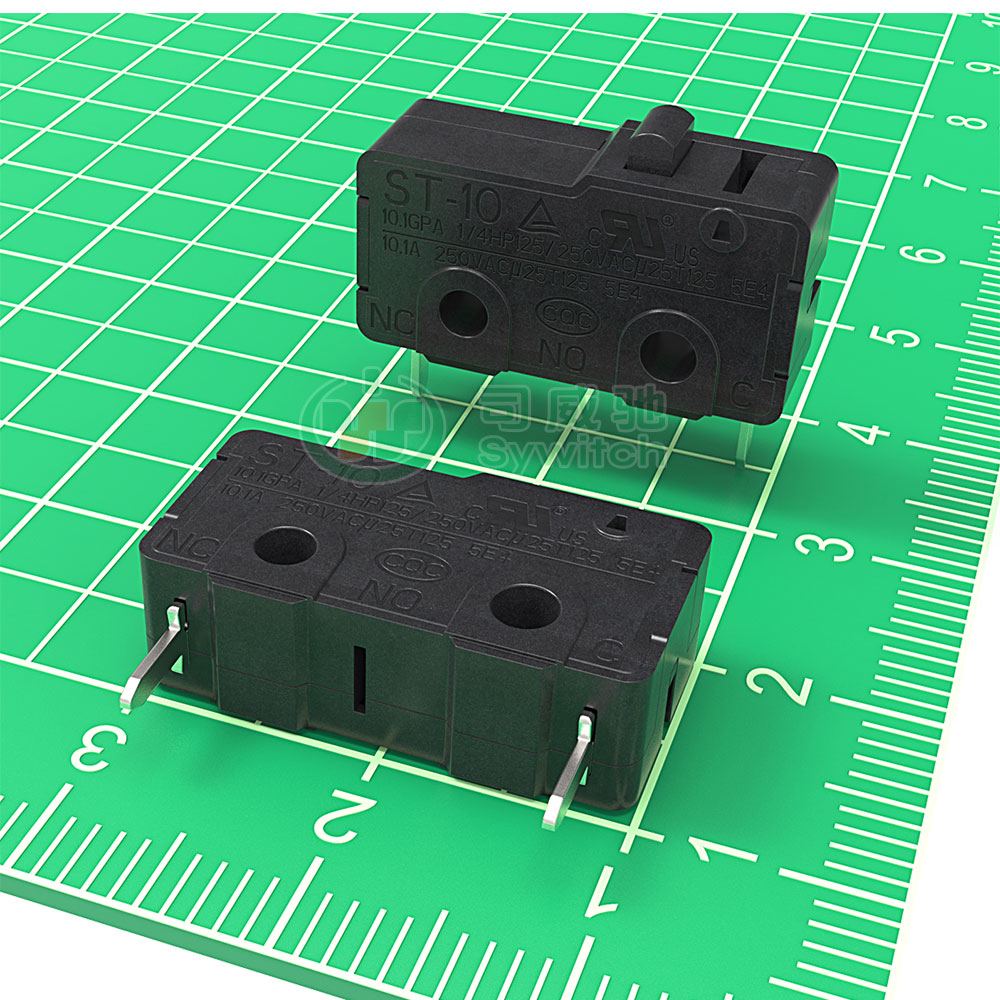

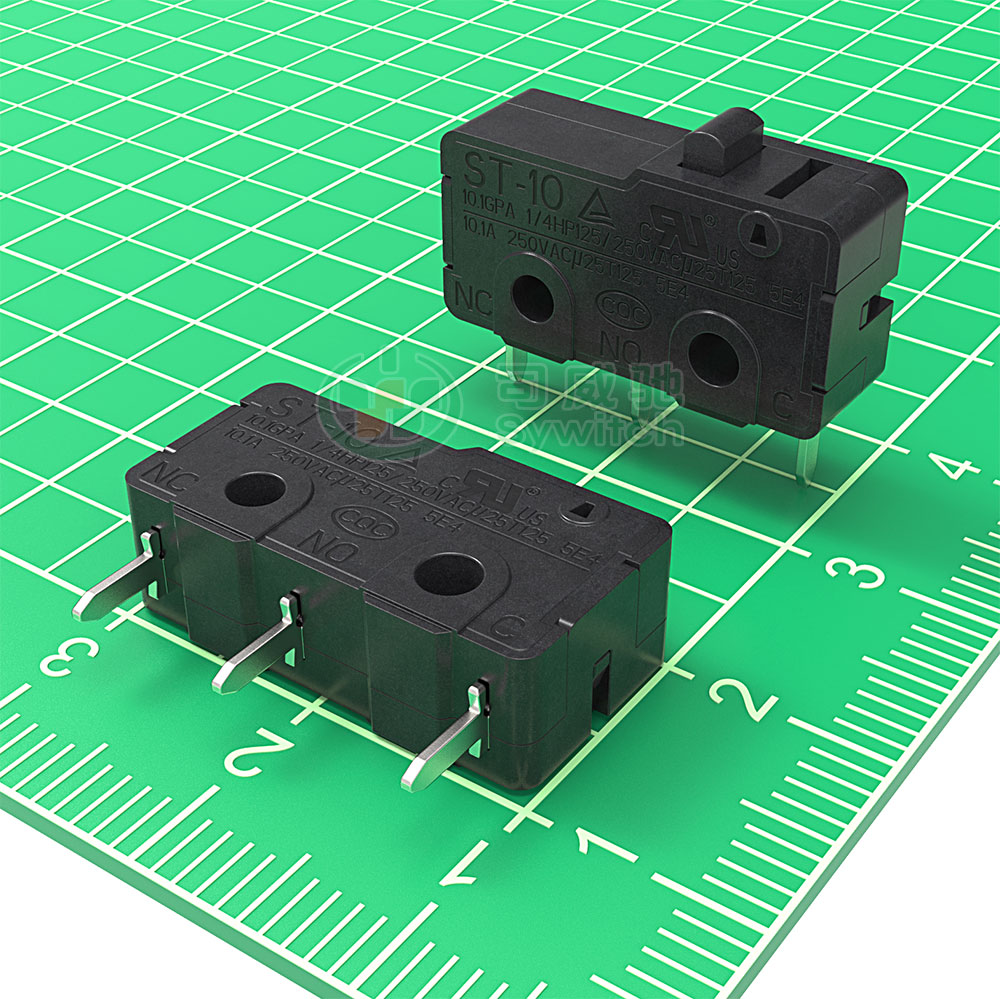

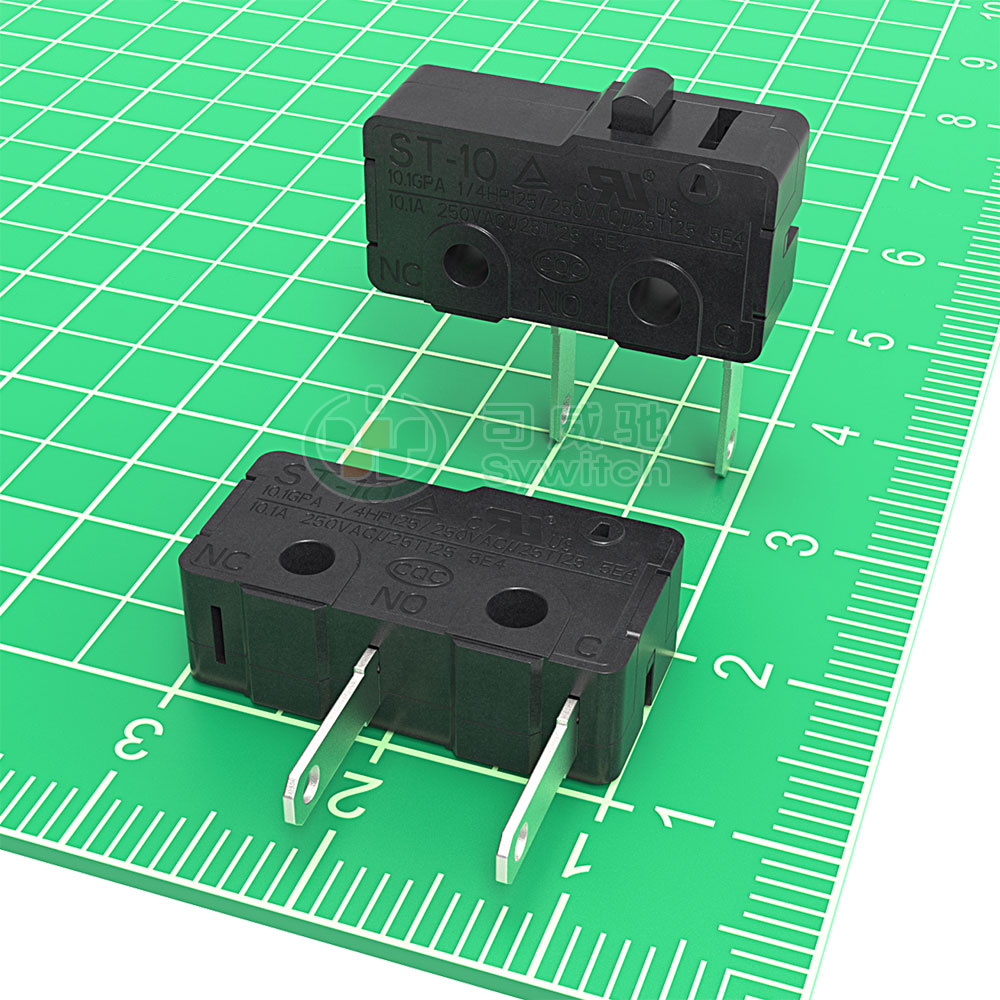

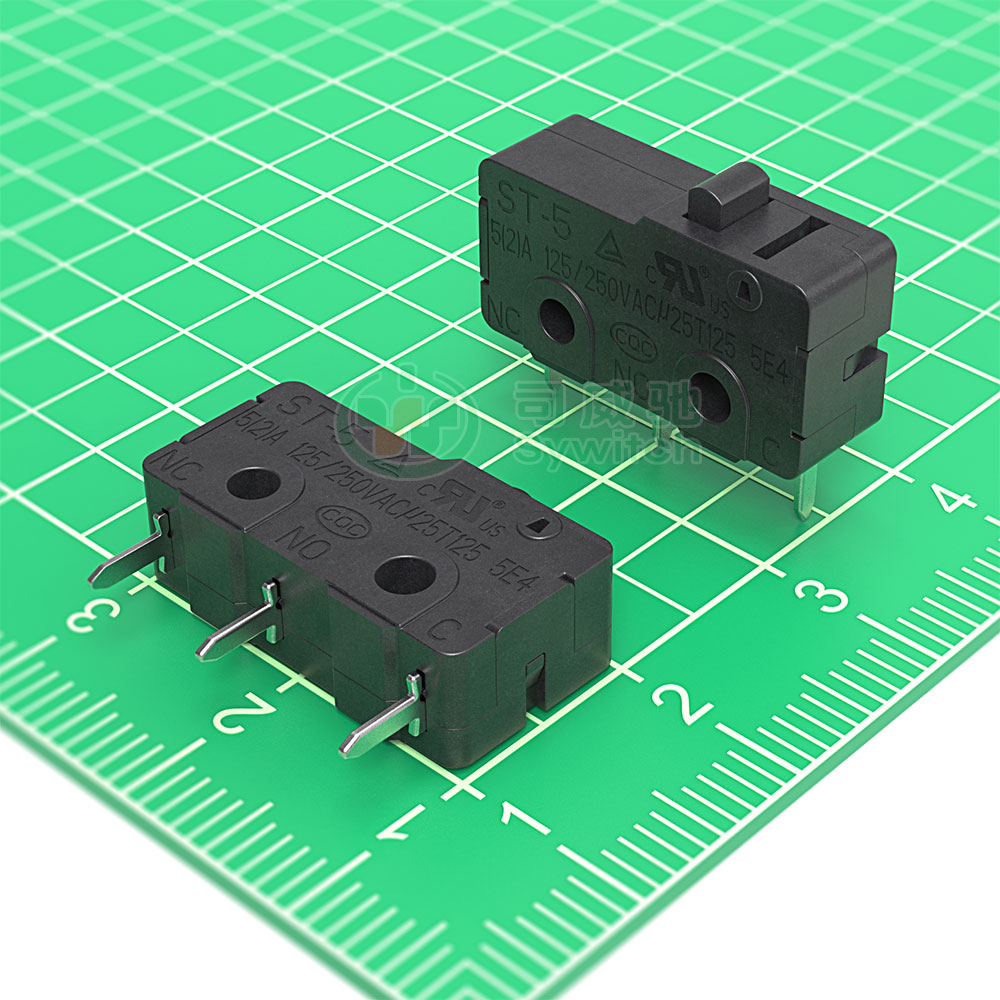

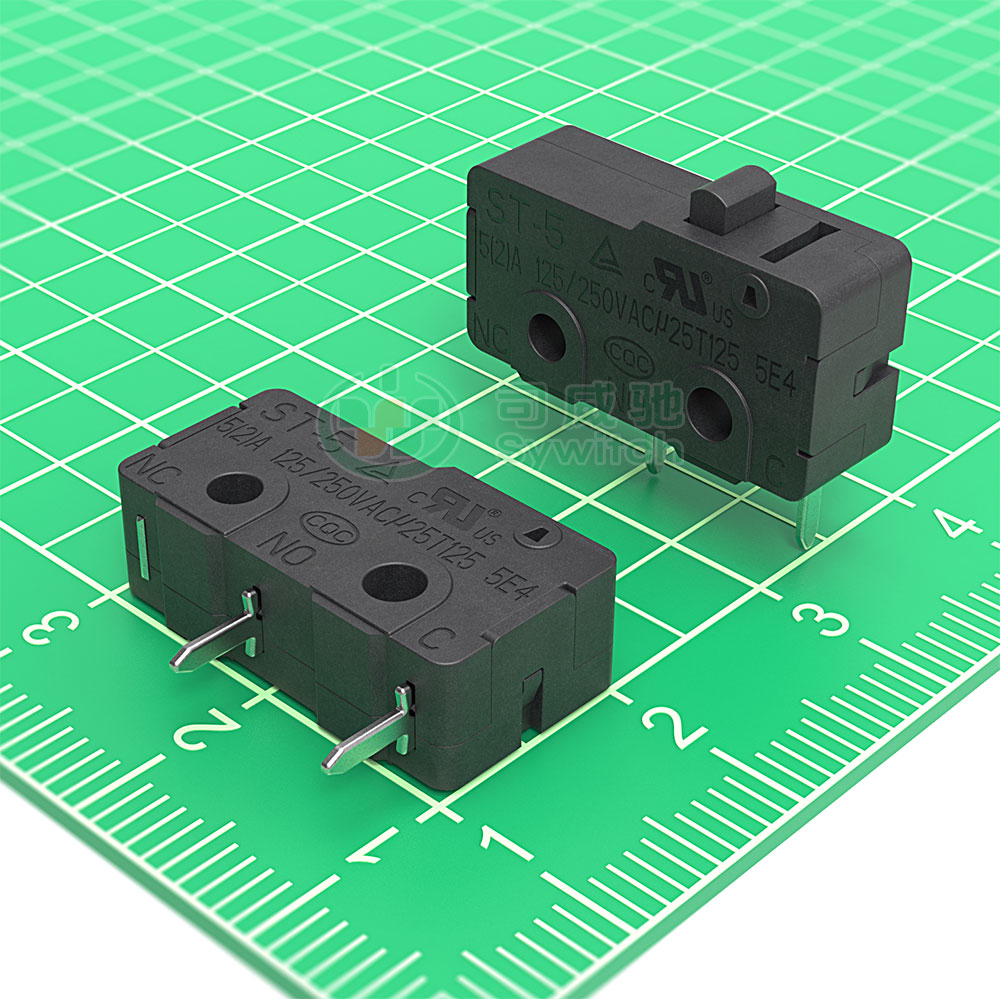

The Terminal is also a critical electrical structure in a micro switch, responsible for the input and output connections between the switch and the device. There are typically several types of terminals available, including Solder Terminals, Quick-Connect Terminals, PCB Terminals, and Bent-Pin Terminals, each designed to ensure reliable connections of the micro switch in various scenarios. Among them, Bent-Pin Terminals are particularly suitable for scenarios where the micro switch needs to be mounted on the side, providing a secure and reliable connection.

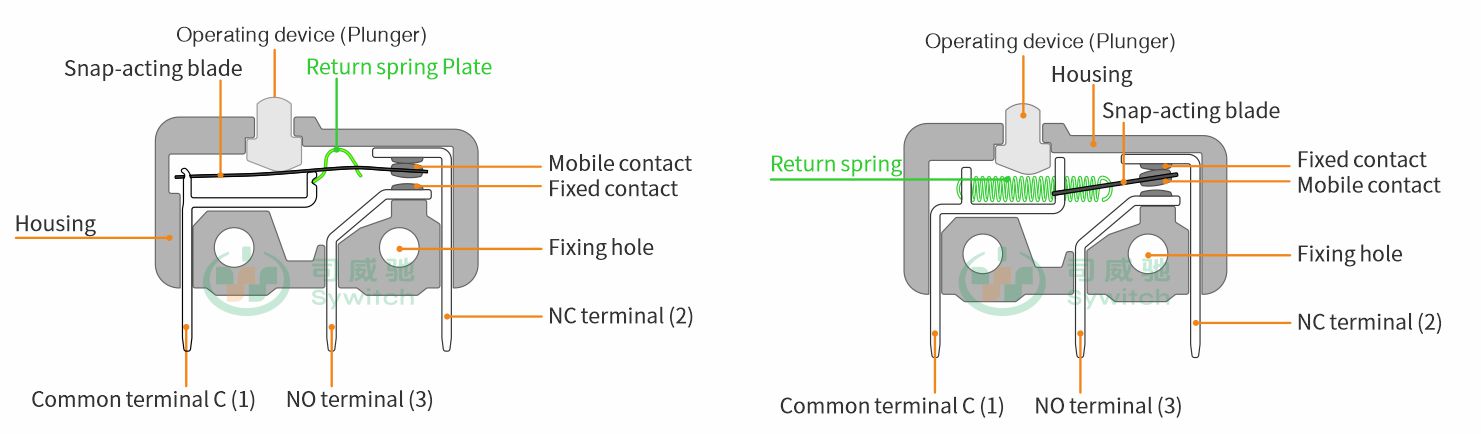

The Return Spring Plate is essential for restoring the Plunger and Mobile Contact to their initial positions after the micro switch is pressed and released. It typically comes in two forms: Spring or Spring Plate. For more detailed information, please refer to the reset structure of the micro switch using Spring or Spring Plate.

Furthermore, the Fixing Hole is a crucial structure in a micro switch that ensures its secure installation on a device. To mount the micro switch on a device or to achieve a more robust installation, it is necessary to pre-drill screw holes on the device according to the dimensions of the Fixing Hole. The micro switch can then be fastened onto the device using screws threaded through the Fixing Hole. For specific Fixing Hole dimensions and installation considerations, please refer to the product specifications or consult the customer service team at Sywitch Technology.